Text from Niamh Shaw’s talk

Technologies Driving Factory 4.0 in 2018 | Barry Kennedy

Barry Kennedy, IMR

Barry introduced his presentation with a personal story of when he had cancer and linked it to how the Irish Manufacturing Research centre of which he is CEO approached its research. He then discussed what IMRs function was to ‘demystify, derisk and deliver emerging technologies for manufacturing industries. He discussed the thematic areas that they are currently prioritising such as Augmented Reality, Virtual Reality, Collaborative Robotics, Additive Manufacturing and Industry 4.0 covering data analytics, optimisation of manufacturing lines.

Barry introduced his presentation with a personal story of when he had cancer and linked it to how the Irish Manufacturing Research centre of which he is CEO approached its research. He then discussed what IMRs function was to ‘demystify, derisk and deliver emerging technologies for manufacturing industries. He discussed the thematic areas that they are currently prioritising such as Augmented Reality, Virtual Reality, Collaborative Robotics, Additive Manufacturing and Industry 4.0 covering data analytics, optimisation of manufacturing lines.

He explained why manufacturing was important citing the demise of the TV industry in the US and Europe before moving on to show how important manufacturing was to the island of Ireland. He quoted numbers of 36% GDP from the IDA versus an EU average around 15% GDP and showed that indigenous manufacturing accounted for over 60% of manufacturing in Ireland and that’s with a backdrop of MNC investment into Ireland which is the envy of most other countries in the World.

Barry spoke of the challenge and opportunities of emerging technologies for industries. He discussed the 4 industrial revolutions in the context of business models and who controlled the industries in the 4 stages. He showed how digital technology has disrupted traditional business models such as the hotel industry with Airbnb and the taxi industry with Uber. Barry then moved on to look at how industries such as the car manufacturers in Detroit were decimated during the automation revolution during Ind 3.0 and warned that industries in Ireland cannot be complacent and afford to be left behind.

His talk then moved onto some examples of emerging technologies such as AI (Artificial Intelligence). He discussed how AI for instance has the power to do good such as interpret better than a human things such a CT scans in medicine but equally talked of a case where an AI engine online became a racist. He warned that as we embrace these technologies we do so with our eyes wide open and discussed the need for, in certain circumstances, for potential legislation to be considered. He stated that Ireland needs to decide the kind of society it wants and to look at the ethics of these systems. Nonetheless he stressed these technologies are here and that we must embrace them for all the good they bring.

He then went on to talk about the advantages of digitising of manufacturing lines, collaborative robotics, additive manufacturing / 3D printing before answering questions from Matt Cooper and the audience.

Design Lessons for Industry | Ray O’Cinneide

Ray O’Cinneide, Tyndall Institute

“10 years ago Brendan O’Flynn watched Tom Cruise in minority report manipulating a screen with a glove and asked ‘wouldn’t it be cool’ if we could create that” said Ray O’Cinneide in kicking off his talk on the story of the Smart Glove.

“10 years ago Brendan O’Flynn watched Tom Cruise in minority report manipulating a screen with a glove and asked ‘wouldn’t it be cool’ if we could create that” said Ray O’Cinneide in kicking off his talk on the story of the Smart Glove.

Tyndall had technology and the research capability to make it and the basic idea evolved over a number of years. Early version fell off hands and broke and they knew they needed to make it into something that people want. To do this they partnered with Bray based Design Partners who helped focus on three things

- User experience (UX) for customers

- Customer discovery

- Manufacturability

The process helped them think about customers and also the need to have robust software without which the hardware is useless. Over series of iterations the Smart Glove has received awards and finally went on the NDRC discovery programme.

Through the programme they learnt to

- Get failure out of the way early

- Find out whats wrong with the process

- Helped to think about the impact and where it could be used (target audience)

The €150 billion industry for AR and VR was a natural market for them with a vertical focus on the segments that would most benefit including:

- Medical and surgical – (practice hand movements in virtual reality)

- Military – can do a dry run

- Gaming

Ray finished his presentation by demonstrating the glove in action that allows the user to reach into that simulated virtual world. During the group sessions potential uses in the manufacturing sector were expanded.

Designing Success | Cormac Ó Conaire

Cormac Ó Conaire Design Partners

Cormac showcased some of the variety of designs created by the Design Partners’ team and their clients including world-leading products and apps from Panasonic, Google, Logitech, Silvair and S3Connected Health.

Cormac showcased some of the variety of designs created by the Design Partners’ team and their clients including world-leading products and apps from Panasonic, Google, Logitech, Silvair and S3Connected Health.

All of these projects posed different challenges, for instance, when designing a ‘simple’ headset for a mass audience the design team must consider complex ergonomic details, anthropometrics and mechanical engineering because everyone heads are different. His team aims to resolve those complexities, in collaboration with their clients, in a beautifully clean experience for the end users. Cormac also pointed out that an understanding of optimising workflows is crucial when designing digital products to make them look, feel and function better. The products shown had a highly advanced technology behind them, however Cormac stressed that technology is simply an enabler to create meaningful experiences for people, and that it is important to focus less on the technology and more on the experiences it can create.

Cormac also discussed that Irish companies have an opportunity to utilise design as a competitive edge, pointing out that, according to the Design Management Index, companies that embrace design are outperforming others by a large factor. This is also reflected in a Gartner report that records that 89% of competitive advantage is based on customer experience, and not a technological breakthrough or innovation.

Design can often be seen as a cosmetic layer applied but the earlier it is embedded in the new product development process the more impact it can have. New product development is not just about innovation and needs to be thought about holistically. Cormac pointed out how design can bring differentiation, create happier customers and mitigate risk when launching new products, through market analsysis, human-centred design and user testing, respectfully.

Pointing to the power of good design Cormac added creating something beautiful is more than aesthetics and can have a profound impact on people and how they feel.

Design begins with two fundamental questions: Do you know your customers and what do you stand for? The intersection of what your customer is seeking and what you stand for should guide every part of the design experience.

In understanding your customers you need to ask have you spent time with them in their space.

The design process also needs to understand ‘what you stand for’ and not just important for leadership. It must reflect values that can be articulated authentically.

Cormac illustrated these points in work Design Partner did for Logitech G, who decided to refocus on the video gaming space from a position of decline and knew they had to invest in reinventing themselves through design.

Design Partners spent time studying the gaming community which revealed the high stakes nature of gaming (one competition has a prize fund of 17 million). Gamers also employed performance coaches worried about lag in the gamers performance due to poor peripherals. They were not looking for a toy to play with, they were looking for tools to win with. Prior to this Logitech were targeting an older audience. They also studied what Logitech stood for This discovery journey led to a new process including the use of high speed cameras to capture rapid hand movements and demonstrated the rigour that needs to be applied to really understanding the customer and delivering high performance products to them. This collaboration was a huge success for Logitech, who have multiple products as the best selling in the world, with a consistent growth in business.

Cormac finished his talk emphasising the equation for success in new product development being:

Who are your customers + What do you stand for = Reflected in all touch points in the customer experience.

Developing Internal Talent to Meet the Challenging Needs of the Business | Siobhan Geary.

Siobhan Geary Boston Scientific Clonmel. Developing internal talent to meet the challenging needs of the business.

Siobhan Geary Boston Scientific Clonmel. Developing internal talent to meet the challenging needs of the business.

“How much does it cost to hire an employee?” was the opening statement by Siobhan Geary from Boston Scientific, before informing attendees that the average cost is €22-34,000. This is based on the average industrial wage of 45k with the cost ranging from 50 to 70% of the employees first year salary.

“This should be a motivating factor” to develop your internal talent.

In 2010 Siobhan needed to recruit Lean and Operational Excellence personnel but initial job searches came back empty handed. As a stop gap solution, they developed a lean associate role from the operator population and in 2013 decided they needed to standardise the training and upskill these Lean Associates.

Siobhan developed a long list of skills and competencies based on shareholder involvement that were needed. In conjunction with their training department she developed a 12 module programme which including experiential learning.

The initial shock was that the programme would have resulted in 218 hours of classroom time and 476 hours of experiential training. This would have meant taking resource out of the company for 6 months, when its staffing was already stretched.

Outside of the business concerns was the employee motivation, how to define and put together a good value proposition to meet the ‘What’s in it for me?’ These employees already had the job, were getting good feedback and in essences this course was not going to provide any additional opportunities. The employee after all this training would be returning to their original roles.

In Boston Scientifics highly, regulated world qualifications and accreditation are necessary for compliance for these employees to take on other positions.

Siobhan set on the task to see if she could find a body that would accredit this training.

Her feeling was it could be level 7 training. While searching for an accrediting body she still needed to build support for the concept and course with the organisation. To build a compelling vision she created a framework to visualise and contextualise the horizontal integration and vertical alignment of the program to the organisation reflecting how people could fit and move within the organisation.

Then she brought in some different stakeholders within various functions of the company from supply chain, quality, to engineering to help build support and momentum in the program. The feedback was they also had excellent people in each group but they did not have the qualification to advance. They requested an education solution that would meet both the Lean/Op ex needs but also there’s.

This recognition of a bottleneck of talent who are not lacking in capability but rather academic qualification prevents them from moving up in the organisation, required a broader ranging and higher academic solution then originally scoped.

Together with Siobhan, John O Riordan from the training department reached out to the Institute of Industrial Engineering, Tim Byrne and Skillnet, Victoria Wilmott organised a group meeting with other companies in the region to share the problem and potential solutions. Fortunately WIT were present in the form of Darrin Taylor and Aidan Walsh from the Business School, they responded with a Level 7 Lean Fundamental program and a Level 8 Higher Diploma in Operational Excellence programme that covered lots of the key skills and competencies that the business needed.

The real game changer was that WIT would recognise prior learning, industry expertise, as a qualifying factor for the programme. The intense programme (1 year) was easier for employees to commit too and the program structure with direct face time with lectures made it a lot easier for those employees who did not have previous formal 3rdlevel education to settle into the courses. Skillnets also supported the program by providing 20% funding.

As part of the programme Siobhan linked a Value Improvement Project worth €50,000 as an expectation to anyone who successfully applied for the course. The purpose of this was to provide an opportunity to practice the project management element of the course in the business environment and generate a return on investment for the organisation.

The results of the programme have been exception with 53 successful graduates by 2018, 70% of these employees have been promoted, with a further 16 enrolled this year. Feedback from the graduates have been really positive. Programme directors Darrin Taylor and Aidan Walsh also providing glowing references about our employees and how this program is an example of Global Best Practice of academic and industry collaboration.

The business impact of the programme and over past year $8.7 million worth of projects loaded to the VIP system which includes the saving of over $300k on the course cost alone.

Finishing up her presentation Siobhan compared the potential hiring cost for those 37 promoted employees of €1.2 million versus the €220k spent on their education. This represents a 5 times return on investment alone, not to mention the 30X return on the investment based on the $8.7 m worth of projects delivered.

The Real Challenge for Managers | Kevin Eyre

Kevin Eyre began his talk by recalling the great conversations and inputs that took place over the group discussion. For him what is relevant is the talk and not behaviour and how conscious we are of what we are actually saying.

Kevin Eyre began his talk by recalling the great conversations and inputs that took place over the group discussion. For him what is relevant is the talk and not behaviour and how conscious we are of what we are actually saying.

According to Kevin we give a lot of attention to how people think but behaviour (the acts they take) all require the use of language.

It is not possible to do any of these things without the use of language.

What is the effect that talk has on how we think and behave

Can we influence what happens to people?

He encourage people to ponder “How do I feel, how might I be inclined to act once someone tells me what to do versus when someone asks me how I feel.”

This has a massively differently impact.

If someone takes an interest I can quickly get engaged and its my responsibility to take ownership.

All is a consequence of asking a question rather than telling someone what to do.

Kevin outlined the typical challenges that managers face and the different roles they play from Commander, Instructor, Agent Provocateur, Negotiator, Trainer, Mediator, Consultant, Faciilitator, Mentor and Coach. In addition they are also expected to not just respond, but to create A Growth Mindset as well covering

- Collaboration

- Excellence

- Innovation

- Engagement

This demanding challenge and the pressure of what managers feel causes them to sound off.

They spend most of their time telling and suggesting.

“As children we ask, have fun, be curious, moment where everything was amazing, we lose this as managers” added Kevin.

For a manager sometimes talk is a part of our action (Depends on how I interact. What I say and how I say it.), most often, action is a part of our talk and sometimes, our talk is action (what we say is what we are doing).

Lots of behaviour is fixed but talk is habitual and changeable and has a big effect on mood state. It all starts to change behaviour.

In changing our Inter action with employees a sudden change can be alarming.

We need to explain why we are choosing to interact differently and work through this strange new world and way of communicating. We need to be able to talk about the talk as we are changing the relationship.

According to Kevin the real challenge for manager is developing and deploy sensitive, skilful and timely dialogue.

In answering questions from the audience Kevin added that some managers can feel a short term loss of control as they modify their dialogue skills but they find they actually get more control by asking than dictating.

Productivity in Crisis – Sustaining Productivity in an Era of Change | Gerry Cahill

Gerry Cahill Roche. Productivity in Crisis.

Gerry is the Managing Director of Roche’s Pharmaceutical manufacturing facility located close to Ennis in County Clare.

Gerry is the Managing Director of Roche’s Pharmaceutical manufacturing facility located close to Ennis in County Clare.

The facility opened up in 1974, was put for sale in 2016 and is now due to close on at the end of 2019.

In 2016 300 people were let go and the feedback from HR was people were good but didn’t know what they know. They could not sell themselves to employers.

This change in the company’s facility posed a serious management challenge in keeping people engaged for the 3 years of a closure scenario.

How do you turn misery into something positive?

The corporate mandate was the flawless supply of medicine which is life-saving, the only source world-wide with annual revenues of €700 million and produced in a highly regulated environment.

The local role was to upskill, apply skills at work to show success and give candidates successes that they could share in job interviews. Management also wanted to leave the site with pride.

The Change message was clear to delivering above average results will improve job opportunities. A series of lean tools and behaviours were use to articulate the benefits for both the business and theindividual. The individual was rewarded with enhanced employability and building capability while the business received stability and capacity.

A report card in 2017 showed the programme was going in the right direction but with the brakes on with leadership not aligned, managing huge change and work streams not connected. Difficult dialogue asked if management were “content with slightly above average performance”

The 2018 plan improved the process by a top down lean deployment and growing the learning organization with visual management, A3, Kata and leaders standard work enabling the upskilling of employees.

The results from the programme include some solid metrics with

- 75% new roles

- 72% external skills

- 95% LEAN skills

- -8% expenses

- -17% cycle time

- Increase compliance and engagement

- And 1.3 million saved

Gerry finished his presentation by sharing his Leadership learnings including

- Should have a shared common purpose i.e. WHY

- Leaders must lead & roll-model behaviours

- Leaders don’t have all the answers!!!! It’s ok to say I don’t know!!!

- Take time to reflect

- Practice, practice, practice …………

- Resource & Accelerate the Learning & Deployment

- Treat people like adults & build respect

- A learning organisation is fun (and challenging)

Our Journey to Excellence | Judith McMullan

Judith McMullan is Global OpEx Manager, Abbot.

Our Journey to Excellence

Judith currently manages the Shingo program across Abbott Nutrition Supply Chain (ANSC), where they have a number of sites challenging for the Shingo Prize over the next three years. In October 2017, Abbott Nutrition, Sligo were the first site in the ANSC network to receive the prestigious Shingo prize.

When they started the Shingo process three years ago they liked the Enterprise wide nature of the process, how it mirrored their values and behaviours and connected the dots between people, process, purpose and performance offering them an external validation of their excellence journey.

The process now engages everyone, everyday with a culture of continuous improvement and problem solving with all teams working together to achieve enterprise alignment. This is achieved through the deployment of the Management Operating System (MOS), standard work and visual management and is measured through the premier plant balanced scorecard.

Judith explained how the company drove engagement through Behaviour-Based Principles using the Shingo methodology. The Shingo model leverages an interconnection of Guiding Principles, Systems, Tools and Results with culture at its centre. Guiding Principles are aligned to Systems which in turn drive guiding principles. Systems in turn select Tools which enable systems. Tools achieve results and results refine tools. Results also affirm Guiding Principles which drive results. At the centre of all of this is culture manifested in behaviour.

As a hierarchy the Shingo model has results at the top which created customer value, followed one step down by Enterprise Alignment, creating constancy of purpose and systematic thinking. Continuous Improvement focuses on process, embracing scientific thinking, flow and pull value, assure quality at the source and seeking perfection. Finally at the base of the pyramid are cultural enablers by leading with humility and respecting every individual.

Judith shared how the people within ANSC are considered to be their greatest asset across all functional groups and it is the collaboration, shared behaviours and common goal that make them a prize winning organisation.

Abbott Nutrition have achieved MOS implementation and standardisation across 14 plants in the ANSC network, across many cultures, also encompassing the functional groups – demonstrating that excellence is not limited to the shopfloor and is relevant and achievable globally.

Standardisation through MOS

Judith explained the range of Cultural Enabler activities and structures that Abbott have in place to ensure leading with humility and respecting every individual. This includes ensuring Safety is always the number one priority, comprehensive auditing to ensure compliance and continuous improvement, an investment in the development of employees through specific leadership programs such as Mindful Leader, through strong visual management achieved through a 5-tiered meeting process, and a culture of recognition of their pledge behaviours.

According to Judith one of the biggest complements during a Shingo visit was when the Shingo examiners shared with the leadership team how it was not easy to distinguish leaders from managers or associates because they had built a strong culture of leading with humility and respecting every individual.

Judith shared how ANSC have evolved on their excellence journey, continuously challenging the tools, systems and measures they have in place and if they are driving an improvement in performance. Asking questions such as “If it is not adding value or making a difference, why are we using it or measuring it?” One such example is in the revisions to visual management, allowing room for personalisation as opposed to stringent standardisation to ensure it is driving results and meeting the needs of individual teams.

The customer is at the heart of everything that Abbott Nutrition do, with their products spanning the continuum of health, and providing life-enhancing nutritional products for infants through to the elderly. To remind of this and ensure they never become complacent, they hold an annual customer appreciation day. Judith shared the most recent example of this in Sligo, where a father of two daughters dependant on nutritional devices manufacturing at the Sligo facility came to site to share their story with all employees. This provides an opportunity to understand the user experience, look at opportunities for further improving our product and touch the hearts and minds of employees by bringing the customer insight to the shopfloor.

Abbott Nutrition to directly correlate their operational excellence journey to improved business results and cost improvements year over year, with the systems and tools implemented allowing employees to work smarter, not harder. Since the deployment of their Management Operating System, they have seen their journey develop through the various phases of Build, Grow, Evolve and today it is in a Sustain phase, yet continuing to challenge and improve.

On Oct. 12th 2017, Abbott Nutrition Supply Chain, Sligo Ireland, received notification from the Shingo Institute that they had won the prestigious Shingo Prize per the recommendation of the Shingo examiners. This was a proud moment for all Sligo employees and the entire Abbott Nutrition division, being the first site to have received this external validation of their performance.

Problem Solving – John Quirke

John Quirke, SA Partners

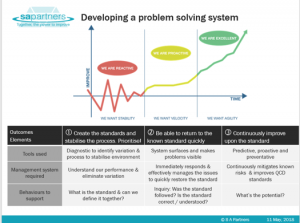

Two common themes come up when we review how businesses approach problem solving.

Two common themes come up when we review how businesses approach problem solving.

One. The lack of a joined up system to enable effective problem solving across the business.

And two. The level and quality of process focus within the organisation.

Given the development of enterprise excellence thinking, those organisations that achieve consistent levels of sustainable excellence are hard wired to think in core business systems and the behaviours those systems need to support.

In his presentation John asked the audience a series of questions.

- How many have standard approach problem solving?

- How many have visual management boards in their work areas?

- Is there a good quality problem solving visible on those boards and is it current to the ‘now’?

- Do you see the same systems and practices at the senior management levels, and are leaders consciously coaching for good behaviours to support effective problem solving?

John pointed out that we need different ‘heads on us’ when we approach problems depending on the ‘Lean maturity’ of the organisation. If we are in a place where there is constant firefighting and we cannot predict outcomes with confidence then our problem solving focus is on identify standards and finding new ways for the process to ‘speak to us’ so we can understand better what is going on. In more mature organisations the focus becomes prediction and likelihood and also questions around what is possible? Or, what if?

In problem solving there is a tendency to focus on the tool not the overall systems and a the behaviours needed.

A second problem is the level and quality of process focus.

In order to demonstrate this John asked the group to carry out a card experiment where attendees attempted to drop a card onto a flipchart size sheet of paper. Following the standard process almost none of the tables got the card on to the sheet. John then went through the ‘normal’ problem solving activity and the way organisations can jump to solutions without really understanding what is at the core of the process.

Using the same standard conditions with one slight change (how the card is held) John demonstrated the problem related to the control of the aerodynamics of the card’s flight to the target area. John explained that by understanding the aerodynamics of the cards flight and what was need to ensure a perfect flight, we could then create well thought out standard work documents that are truly applicable to the process and will ensure consistent predictable results.

Using the same standard conditions with one slight change (how the card is held) John demonstrated the problem related to the control of the aerodynamics of the card’s flight to the target area. John explained that by understanding the aerodynamics of the cards flight and what was need to ensure a perfect flight, we could then create well thought out standard work documents that are truly applicable to the process and will ensure consistent predictable results.

His advice was we need to focus on experimentation and curiosity to allow the development knowledge which enables us to better investigate what is happening in the processes.

Problem solving should be a learning experience a discovery. Sometimes we are finding things and solving problems that nobody has solved before. The quality of the documentation controlling this problem the story telling around how we discovered and controlled it in a way is our legacy.

In order to achieve this, we need to connect with and enable our innate human intuitiveness. The stone age did not end because we ran out of stone! Homo Sapiens is hard wired to prod, poke, investigate, grunt ‘why’. and then work as tribe to make things better. This is what we are.